Open Bore Piling

Open Bore Piling

The open bore piling method allows for a greater range of sizes and depths of pile. All of the rigs at our disposal are extremely high powered which make them ideal for dealing with most ground conditions.

Our bored piling machines are capable of installing pile from 150mm to 750mm to a maximum depth of 30 metres and once the required depth is reached, a reinforcing steel cage can then be installed and the pile concreted.

Open bore piling for large and small sites

Open bore piling being used for years, is utilised both by small and large-scale construction projects with varied types of ground substrate. Our piling company provide integrated steel and concrete solutions producing less vibration, making it retrofit for all kinds of building structures.

Construction process of bored piles

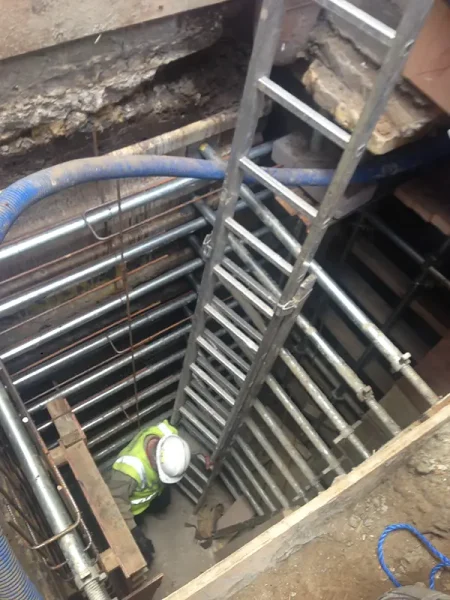

- Bored piling machines are used to drill vertical holes in the soil to begin the building. Our ultra-modern machines are built with all drilling instruments, buckets and grabs to aid in the removal of soil and rocks during the drilling operation.

- Our large diameter bored pile can reach a depth of 60 m and a diameter of 2.4m.

- Until the pile is inserted, a temporary steel cylinder and sleeve are put into the drilled hole.

- A rebar cage for the pile is fitted into the hole, and then it is completely filled with the concrete

- The top layer of piles is covered and protected, ready for the structure above to be constructed.

Open Bored Piles for Cohesive Soil

Our advanced rigs are cost-effective for usage on wide open sites with cohesive grounds, as well as chalk and some sands. Smaller models are appropriate for interior use.

Because rotary augers produce less vibration, they are appropriate for usage near buildings or subterranean services. It is also feasible to use these rigs for down-the-hole hammer drilling, which allows piles to be secured in rock or dense material.

Rotary Bored Piling services by 4SP Group

Rotary bored piling removes debris and dirt using state-of-the-art rigs and specialised drilling equipment such as buckets and augers. Our bored piling contractors use the tools to repeatedly dig the earth, eliminate soil and insert piles to the desired depth.

Unstable terrain

When the ground condition is weak, a temporary and permanent casing is employed to allow the piles to be bored without collapsing the earth. The ground is unstable along the whole pile length due to groundwater incursion or deeper lose ground.

Our professionals use full-depth casing or drilling fluid to level the ground.

What are the Primary Benefits of Open Bore Piling?

Following are the main benefits of bored piles or drilled shafts when compared to conventional footing or other types of piling.

- Through compressible, soft or expanding soil, piles of different lengths can be stretched into adequate bearing material.

- Pile depths can be increased by allowing for frost presentation and seasonal moisture change.

- Large excavations and subsequent backfill are kept to a minimum.

- Low vibration causes little or no disruption to the surrounding area.

- High-capacity caissons are built by enlarging the base of the pile shaft to three times its diameter

- Open bored piles have higher capacity and better economics than driven piles in various designs.